| Step | | Procedure & Parts & Tools |

| 1 |

|

REMOVE 3 SCREWS FROM HANDLE COVER

| Torx T20 |

|

|

| 2 |

|

REMOVE HANDLE COVER FROM THE MACHINE

|

| 3 |

|

VISUALLY INSPECT THE HANDLE MECHANICS TO MAKE SURE HALL SENSOR IS IN PLACE AND HANDLE MECHANICS ARE INSTALLED CORRECTLY (AFTER INSTALLING THE SPRING SHOULD BE VISIBLE). MOVE THE LEVERS UP AND DOWN TO CHECK COMPONENTS ARE MOVING CORRECTLY.

|

| 4 |

|

REMOVE THE WIRES FROM THE MICROSWITCH. PLACE THE LEADS WHERE THE WIRE CONNECTORS WERE.SET THE VOLT METER TO CONTINUITY. FLIP THE SWITCH. IF THE VOLT METER BEEPS, THE MICROSWITCH IS OKAY.

| Volt meter (True RMS capable) |

&Width=100)

|

|

| 5 |

|

REMOVE THE 5 SCREWS FROM THE CONTROL PANEL COVER.

| Torx T20 |

|

|

| 6 |

|

REMOVE THE CONTROL PANEL COVER.

|

| 7 |

|

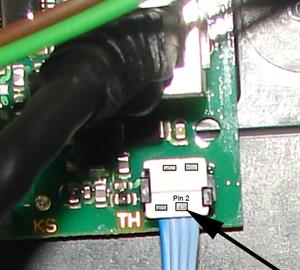

FLIP THE CONTROL PANEL OVER AND LOCATE THE HALL SENSOR PIN BLOCK (SHOWN WITH ARROW HERE).

|

| 8 |

|

REMOVE THE 2 BOLTS AT FRONT OF FRAME AND OPEN MACHINE. LOCATE THE BLACK PLUG WITH 1 RED WIRE AND 1 BLACK WIRE. PULL THE PLUG TO DISCONNECT IT FROM THE CONTROL BOARD. WHILE THE MACHINE IS OPEN, TAKE THE VOLT METER BLACK LEAD AND CLIP TO THE NEGATIVE POST ON THE BATTERY.

|

| 9 |

|

CLOSE THE MACHINE AND INSERT THE RED LEAD INTO PIN 2 ON THE CONTROL PANEL, SHOWN HERE. TURN THE KEY ON, ACTIVATE THE MACHINE, SET THE VOLT METER TO VOLTAGE. VOLT METER SHOULD READ APPROX. 5 VOLTS. IF SO, THE HALL SENSOR IS OKAY. NOTE: YOU WILL NEED TO USE A PIERCING LEAD (FINE POINT) ON VOLT METER.

| Volt meter (True RMS capable) |

&Width=100)

|

| Wrench-Allen metric 6.0mm |

|

|